- Accessories for Pressure Instruments

- Differential Pressure Gauges

- Differential Pressure Switches

- Differential Pressure Transmitters

- Compound range Pressure Switches

- Vacuum Switch

- Thermowell

- Temperature Sensors

- Temperature Switches

- Temperature Transmitters

- Accessories for Flow Instruments

- Mechanical Flow Gauges

- Flow Sensors

- Flow Rate Indicators

- Flow Meter

- Flow Switches

- Flow Transmitter

- Accessories for Level Instruments

- Digital Level Indicators

- Level Switches

- Level Transmitters

- Mechanical Level Gauges

- Vibration Switches

- Customized Process Indicator and Controllers

- Control Panels

- pH Testing Products

- DO2 Instruments

- TDS Instruments

- ORP Instruments

- Conductivity Instruments

- Pressure Measuring and Control Instruments

- Pressure Switches

- Pressure Transmitters

- Level Gauges

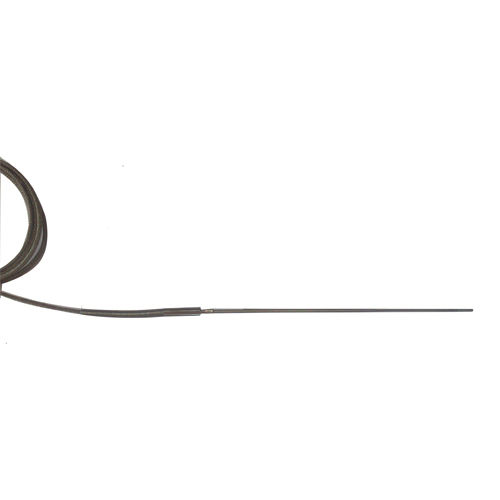

RTD with Adjustable Ferrule nut Connection with Thermowell

2000.00 - 10000.00 INR/Piece

Product Details:

- Resistance 100 Ohm at 0C

- Output Resistance (Ohm)

- Theory Measures temperature by correlating the resistance of platinum with temperature change

- Type Pt100 Resistance Temperature Detector (RTD)

- Accuracy Class A as per IEC 60751

- Operating Voltage Typically 110V DC (excitation for measurement circuit)

- Output Voltage Not applicable (Resistance output)

- Click to View more

X

RTD with Adjustable Ferrule nut Connection with Thermowell Price And Quantity

- 2000.00 - 10000.00 INR/Piece

- 1 Piece

RTD with Adjustable Ferrule nut Connection with Thermowell Product Specifications

- -50C to +85C

- 100 Ohm at 0C

- Typically 110V DC (excitation for measurement circuit)

- Resistance (Ohm)

- Class A as per IEC 60751

- Not applicable (Resistance output)

- Measures temperature by correlating the resistance of platinum with temperature change

- Pt100 Resistance Temperature Detector (RTD)

- -20C to +85C

- -50C to +400C

RTD with Adjustable Ferrule nut Connection with Thermowell Trade Information

- Cheque

- 1 Piece Per Day

- 2-3 Week

- Australia, South America, Eastern Europe, Middle East, Central America, Western Europe, Asia, North America, Africa

- All India

Product Description

RTD with Adjustable Ferrule nut Connection with Thermowell

- We manufacture all varieties of RTD's - pT-100, pT200, pT-500 & pT-1000 (optional with Mineral Insulated)

- Contact parts - SS304, SS316 or, special as per request.

- Probe diameter - Minimum 3 mm upto 15 mm.

- Temperature Range coverage - from -50 degree C up to 400 dehree C

- Electrical Connections - Simplex, Duplex and Triplex

- Process Connections types : Fixed Threaed type, Adjustable Nut & Ferule type, Flange type, Triclover type etc.

- Type of Terminal Housings - Flying Leads, Weatherproof Housing, Flameproof Housing, 2 Pin Round Connector etc.

- Max. Pressure - 5 bar standard (Optional 10 bar, for higher pressure applications, use suitable Thermowell)

Note :To receive quick response, please provide your basic requirement details and max.Application information.

Exceptional Sensor Flexibility and Customization

This RTD is engineered to cater to a wide range of industrial requirements, featuring support for 2/3/4-wire configurations and customizable thermowell lengths, diameters, and materials (SS304/SS316). Its broad adaptability ensures seamless integration into diverse applications such as power plants, chemical processing, and general industry usage.

Robust Construction and Reliable Performance

Constructed with durable stainless steel and designed for immersion via a thermowell, this sensor offers ingress protection of IP65 or IP67, depending on the head type. Its Class A accuracy and rapid response of less than 10 seconds provide dependable real-time monitoring for critical processes, even in harsh environments.

Easy Installation and Simple Maintenance

Fitted with an adjustable ferrule nut and process connection options like 1/2" BSP, the RTD allows straightforward threaded or flanged mounting. The unique feature of sensor replacement without disturbing the ongoing process minimizes system downtime, reducing maintenance costs and operational interruptions.

FAQs of RTD with Adjustable Ferrule nut Connection with Thermowell:

Q: How is the RTD with Adjustable Ferrule Nut Connection with Thermowell typically installed?

A: This RTD is designed for immersion installation using a thermowell, which can be mounted via threaded or flanged connections (such as 1/2" BSP). The adjustable ferrule nut allows precise positioning and ensures a secure fit, making it suitable for various industrial process applications.Q: What makes the adjustable ferrule nut connection beneficial for industrial users?

A: The adjustable ferrule nut enables easy installation and sensor positioning within the thermowell. A key benefit is the ability to replace the sensor element without halting or disturbing the ongoing process, which saves time and reduces maintenance-related downtime.Q: When should I select a specific thermowell material or length for my application?

A: Thermowell materials such as SS304 or SS316 are chosen based on the process environments chemical compatibility and required corrosion resistance. Length and sheath diameter can be customized in line with process vessel requirements to ensure accurate temperature measurement and sensor protection.Q: Where can this RTD be effectively used?

A: This RTD is ideal for use in industrial, chemical, power, and process plants. Its robust construction and high ingress protection suit it for harsh environments where reliable and accurate temperature monitoring is critical.Q: What is the typical response time and accuracy of this RTD sensor?

A: The RTD features a fast response time of less than 10 seconds when used in liquid with a thermowell, and delivers Class A accuracy in compliance with IEC 60751, ensuring precise temperature readings.Q: How does the sensor output work, and what does it require for operation?

A: The RTD sensor operates on the resistance principle, offering a direct ohmic output (typically 100 Ohm at 0C for Pt100). It does not generate a voltage output but requires an excitation voltagemost commonly 110V DCwithin the measurement circuit for accurate resistance readings.Q: What is the practical usage process for replacing the RTD sensor in this configuration?

A: If the sensor element needs replacement, simply loosen the adjustable ferrule nut, withdraw the sensor, and install a new one. This process can be performed without removing the entire thermowell or interrupting the process flow, providing operational efficiency and easier maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Temperature Sensors' category

|

NK INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS