- Accessories for Pressure Instruments

- Differential Pressure Gauges

- Differential Pressure Switches

- Differential Pressure Transmitters

- Compound range Pressure Switches

- Vacuum Switch

- Thermowell

- Temperature Sensors

- Temperature Switches

- Temperature Transmitters

- Accessories for Flow Instruments

- Mechanical Flow Gauges

- Flow Sensors

- Flow Rate Indicators

- Flow Meter

- Flow Switches

- Flow Transmitter

- Accessories for Level Instruments

- Digital Level Indicators

- Level Switches

- Level Transmitters

- Mechanical Level Gauges

- Vibration Switches

- Customized Process Indicator and Controllers

- Control Panels

- pH Testing Products

- DO2 Instruments

- TDS Instruments

- ORP Instruments

- Conductivity Instruments

- Pressure Measuring and Control Instruments

- Pressure Switches

- Pressure Transmitters

- Level Gauges

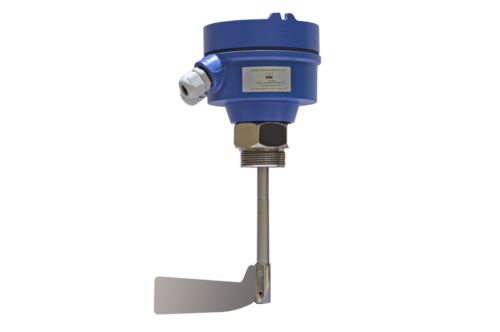

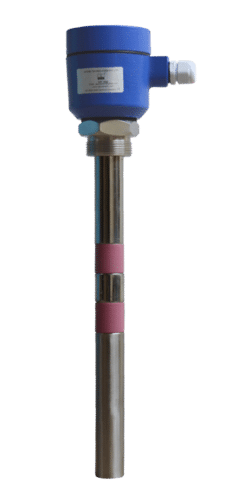

Level Switch - Rotating Paddle type with single Vane Paddle

7000 INR

Product Details:

- Mechanical Life >1 million operations

- Automation Grade Semi-Automatic/Automatic

- Finish Type Industrial Powder Coated

- Protection Level IP65

- Max. Current 5A

- Circuit Type SPDT (Single Pole Double Throw)

- Response Time <1 second

- Click to View more

X

Level Switch - Rotating Paddle type with single Vane Paddle Price And Quantity

- 7000 INR

- 1 Piece

Level Switch - Rotating Paddle type with single Vane Paddle Product Specifications

- 5A max.

- -10C to +85C

- 100 M at 500 VDC

- 250 VAC

- Semi-Automatic/Automatic

- Threaded (Typically 1 BSP or NPT)

- Rotation angle not less than 90

- Industrial Powder Coated

- Single

- -10C to +85C

- Single-pole

- >1 million operations

- Approx. 1.5 kg

- SPDT (Single Pole Double Throw)

- 5A

- 100 m

- IP65

- Level Switch - Rotating Paddle type with single Vane Paddle

- <1 second

- 220/250V AC

Level Switch - Rotating Paddle type with single Vane Paddle Trade Information

- Cheque

- 1 Piece Per Day

- 2 - 3 Week

- Carton Box

- Western Europe, Eastern Europe, Middle East, Central America, Africa, South America, Australia, Asia, North America

- All India

Product Description

Level Switch - Rotating Paddle type with single Vane Paddle

We have Rotary Paddle type Level Switches which are recommended only for dry mediums like powder, granuls, pallets etc.

Salient Features:

Flexible coupling (optional as per application) Robust, dust and watertight housing . Extended Probe possible. Extended life by motor shut off design. sealed bearings. Interchangeable paddle assemblies, Magnetic Clutch mechanism

Technical Specifications (Standard):

SWITCHING UNIT:

- Housing: Aluminum, weather proof, powder coated. Integral with The probe

- Cable entry: 2 nos.

- Ambient temperature: 0 C to +60 C

- Power consumption: 1.9 VA

- Mains Voltage: 230/110 V AC (+/-15%), 50 Hz

- Output: 1 sets of potential free c/o contacts rated at 5 amps, 230 V AC for non-inductive loads.

- Switch status display:Green LED shows Normal, Red LED shows alarm condition.

- Mounting : Screwed - 11/2 BSP (standard) Or Flanged (optional)

- Sense rod : Stainless steel, 12 MM DIA

- Paddle : 1 - 4; Paddles depending upon application.

- Operating Temp in : 80 deg for the standard unit. 200C ON REQUEST

Note : To receive quick response, please provide your basic requirement details and max.Application information.

Versatile Level Detection for Bulk Material

This rotating paddle level switch is specifically designed for accurate and dependable detection of solid and powder levels in various storage vessels. Its rugged build and stainless steel paddle ensure long-lasting performance, while the single vane paddle mechanism offers smooth operation, minimizing material build-up and maintenance requirements. Suitable for a wide range of industries, from food to cement, the switch is ideal for monitoring levels in silos and bins.

Easy Installation and Maintenance

With threaded or flanged process connections tailored to your needs, this level switch is quick to integrate into existing systems. The weatherproof, dustproof housing and industrial powder coating ensure reliable operation in challenging environments. The terminal strip inside the housing streamlines electrical connections and service, reducing downtime and facilitating routine inspections.

Reliable and Safe Performance

Designed for semi-automatic or automatic operations, this device utilizes a SPDT output and operates at a safe voltage range, handling currents up to 5A. The product delivers a mechanical life of over 1 million operations, high insulation resistance (100 M at 500 VDC), and fast response time (<1 second), contributing to reliable automation and enhanced operational safety.

FAQs of Level Switch - Rotating Paddle type with single Vane Paddle:

Q: How does the rotating paddle level switch detect material levels in silos and bins?

A: The switch uses a single vane stainless steel paddle that rotates at approximately 1 RPM. When the paddle comes into contact with bulk solids or powders, its rotation is hindered, causing the unit to trigger its output contact (NO+NC), indicating the presence or absence of material at the installation point.Q: What materials are used to construct the shaft and paddle of this level switch?

A: Both the shaft and paddle are crafted from high-quality stainless steel (grades 304 or 316), ensuring excellent resistance to corrosion and abrasion for extended service life, even in harsh industrial environments.Q: Where can this paddle type level switch be used effectively?

A: It is suitable for installation in silos, hoppers, and bins handling bulk solids or powders across industries like cement, chemicals, food processing, or agriculture, wherever reliable point level detection is required.Q: What are the benefits of using this single vane paddle switch over other level detection methods?

A: This switch offers robust mechanical performance, high reliability (over 1 million cycles), a fast response time, and is unaffected by dust, humidity, or changes in material composition. Its IP65 weatherproof and dustproof enclosure ensures stable operation in demanding environments.Q: Which factors should be considered during the installation of this level switch?

A: Consider process connection requirements (threaded or flanged as per request), suitable mounting location for accurate level detection, ensuring environmental conditions within the specified temperature range, and correct wiring via the provided terminal strip for optimal functionality.Q: How is electrical safety ensured in this device?

A: The device is designed with insulation resistance 100 M at 500 VDC, can handle a maximum voltage of 250 VAC, and uses a weatherproof die-cast aluminum housing, providing secure electrical connections and minimizing the risk of short circuits or failures.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Level Switches' category

|

NK INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free