- Accessories for Pressure Instruments

- Differential Pressure Gauges

- Differential Pressure Switches

- Differential Pressure Transmitters

- Compound range Pressure Switches

- Vacuum Switch

- Thermowell

- Temperature Sensors

- Temperature Switches

- Temperature Transmitters

- Accessories for Flow Instruments

- Mechanical Flow Gauges

- Flow Sensors

- Flow Rate Indicators

- Flow Meter

- Flow Switches

- Flow Transmitter

- Accessories for Level Instruments

- Digital Level Indicators

- Level Switches

- Level Transmitters

- Mechanical Level Gauges

- Vibration Switches

- Customized Process Indicator and Controllers

- Control Panels

- pH Testing Products

- DO2 Instruments

- TDS Instruments

- ORP Instruments

- Conductivity Instruments

- Pressure Measuring and Control Instruments

- Pressure Switches

- Pressure Transmitters

- Level Gauges

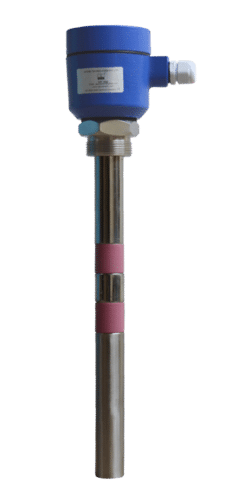

Side Mounted L shaped Miniature SS Float Level

710 INR

Product Details:

- Mechanical Life >1 million actuations

- Number of Module 1

- Temperature Range -10C to +80C

- Circuit Type SPST (Normally Open/Normally Closed)

- Automation Grade Manual/Automatic

- Finish Type Polished Stainless Steel

- Rated Voltage 110V/220V AC/DC

- Click to View more

X

Side Mounted L shaped Miniature SS Float Level Price And Quantity

- 710 INR

- 1 Piece

Side Mounted L shaped Miniature SS Float Level Product Specifications

- Side Mounted L shaped Miniature SS Float Level

- 0.2s

- IP65

- 10 mm

- 50 m

- 0.1A to 0.5A

- Approx. 25-50g

- SPST (Normally Open/Normally Closed)

- Polished Stainless Steel

- -10C to +80C

- 1

- >1 million actuations

- Single Pole

- 0.5A

- 220V AC/DC

- Manual/Automatic

- Side Mounted, L-shaped

- 110V/220V AC/DC

- -10C to +80C

- 100 M at 500VDC

Side Mounted L shaped Miniature SS Float Level Trade Information

- Cheque

- 1 Piece Per Day

- 2 - 3 Week

- Carton Box

- Asia, Australia, Middle East, Central America, Africa, South America, Western Europe, Eastern Europe, North America

- All India

Product Description

- Float type Level Switches are available in Side Mounted versions and Top Mounted Versions.

These type of Level Switch are suitable for Non-Magnetic Fluids only. - Process connection : Flanged, Thread end, Triclover clamp type or, L shaped clampt type

- MOC of Float, Stem and Stoppers: SS 304 , SS 316, PP, Ptfe etc.

- Terminal Housing : Aluminium Housing, Flameproof Housing, DIN Plug or, Flying Leads

- Switching Contacts : SPDT or, SPST. Reed type or, Micro Switch type

- No. of Switches : In Verticle Mounted Version-One no. and two nos. are very common. But we can also give multiple level switches in a special case, but in Side Mounted Version-One switch only

Reliable and Versatile Liquid Level Detection

Engineered for high precision, this side-mounted L-shaped float level switch excels in a variety of liquid monitoring applications. Its robust stainless steel construction guarantees long-term resistance against corrosion and abrasion. With a mechanical life exceeding one million actuations and dependable silver alloy contacts, the device is well-suited for tanks, reservoirs, and process industry environments.

Easy Installation and Customization Options

Installation is straightforward due to the horizontal side-mount design with standardized 300mm wiring and adaptable threaded or flanged coupling. Users can request specific configurations for wire length and connection type, accommodating various tank geometries and industrial requirements for seamless integration.

FAQs of Side Mounted L shaped Miniature SS Float Level:

Q: How is the Side Mounted L-shaped Miniature SS Float Level Switch installed?

A: The switch is installed horizontally on the side of a tank or reservoir using a threaded or flanged connection, as per user specifications. Its L-shaped design allows space-efficient mounting and easy integration with existing systems.Q: What liquids are compatible with the SS304/316 float material?

A: The SS304/316 stainless steel float is highly resistant to corrosion, making it compatible with water, oils, and a range of chemical liquids commonly used in industrial and process environments.Q: Where can this float level switch be effectively used?

A: This device is ideal for liquid level monitoring and control in tanks, reservoirs, process industries, and automation equipmentanywhere accurate fluid detection is required.Q: What are the benefits of the magnetically operated reed switch?

A: Magnetically operated reed switches provide non-contact sensing for high reliability, rapid response time (0.2 seconds), and long mechanical life, reducing the need for frequent maintenance.Q: When should I consider customizing wire length or connection type?

A: Customizing the wire length or choosing between a threaded or flanged connection is advisable if your installation setup requires specific dimensions or compatibility with different vessel designs.Q: What protection features does this switch offer?

A: It features an IP65 protection rating, ensuring resistance against dust and water ingress, and has insulation resistance of 100 M at 500VDC, ensuring reliable performance in demanding environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Level Switches' category

|

NK INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free